- Model stl format & FBX , slice any software… and go to G-code.

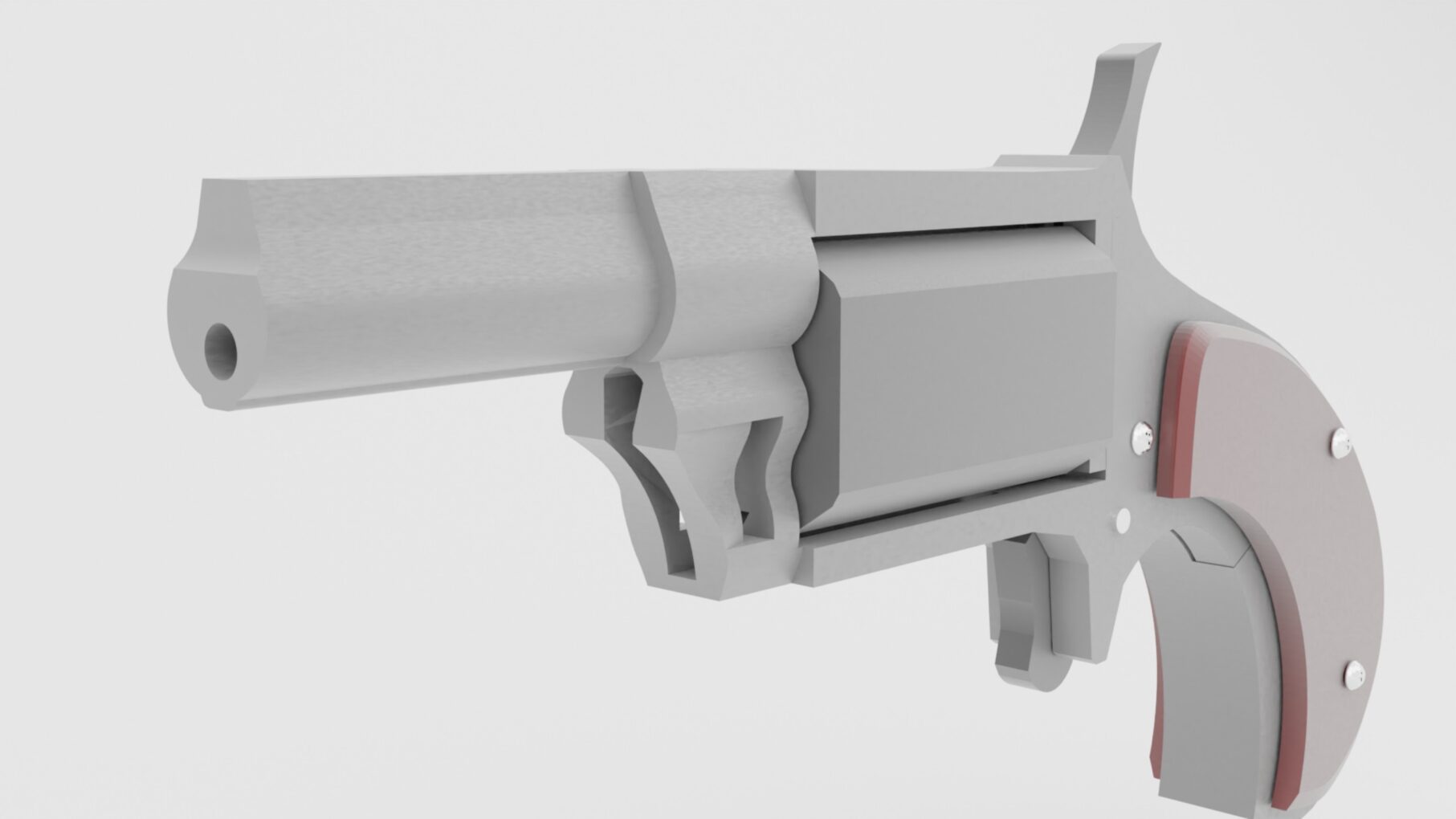

- Watertight 3D model

- High poly model.

- Nice topology for perfect reflections.

- Made with real dimensions.

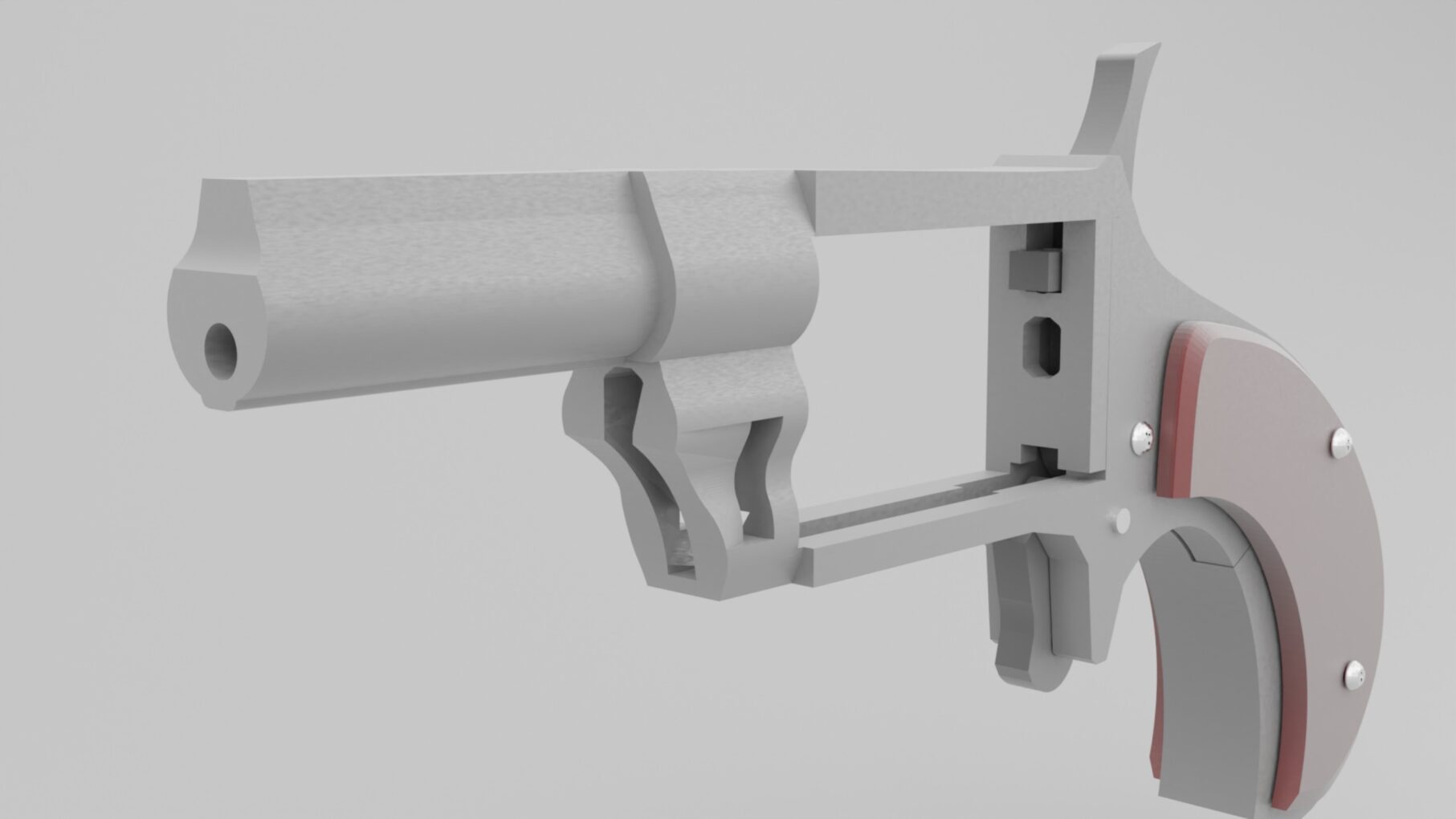

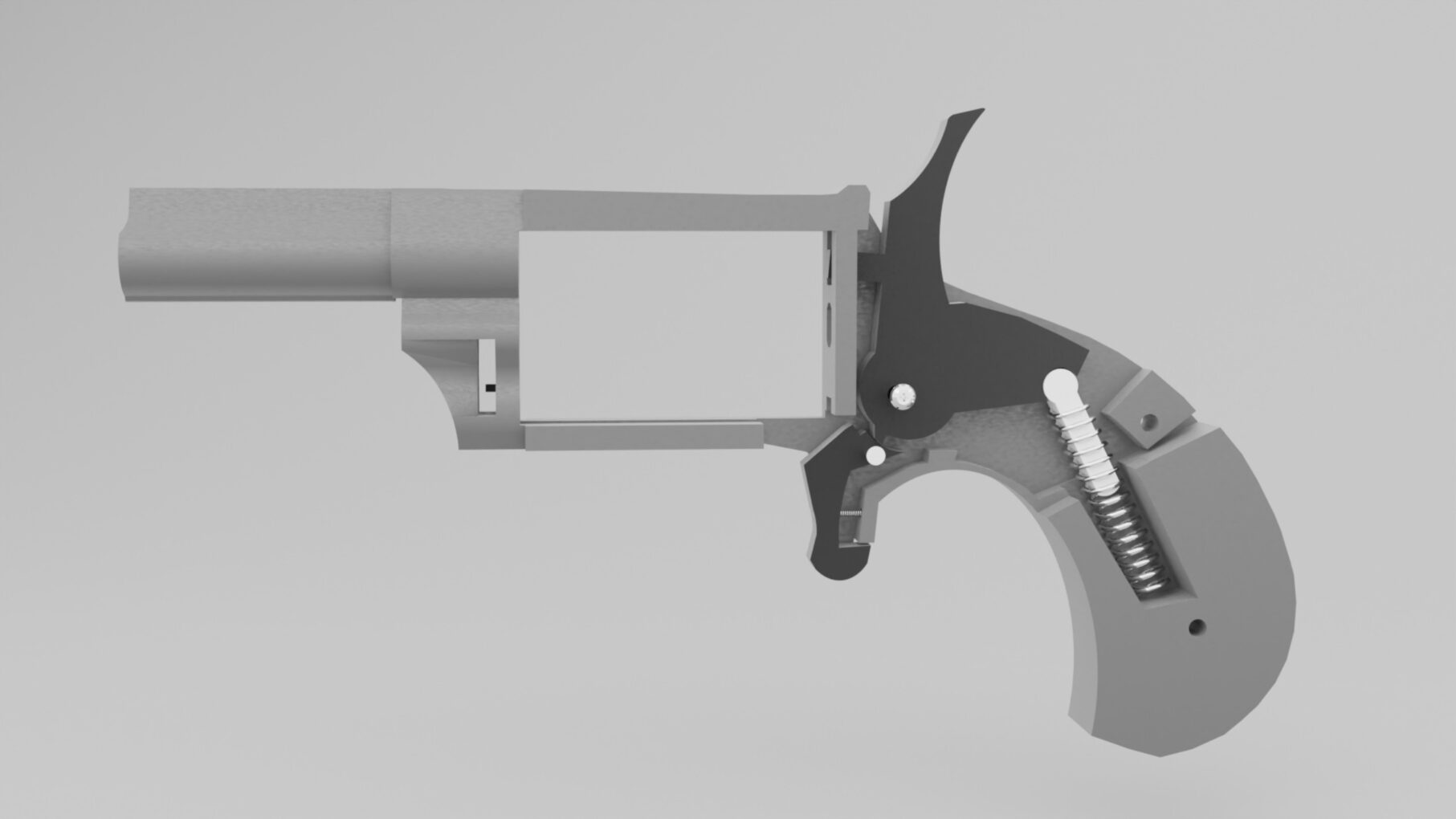

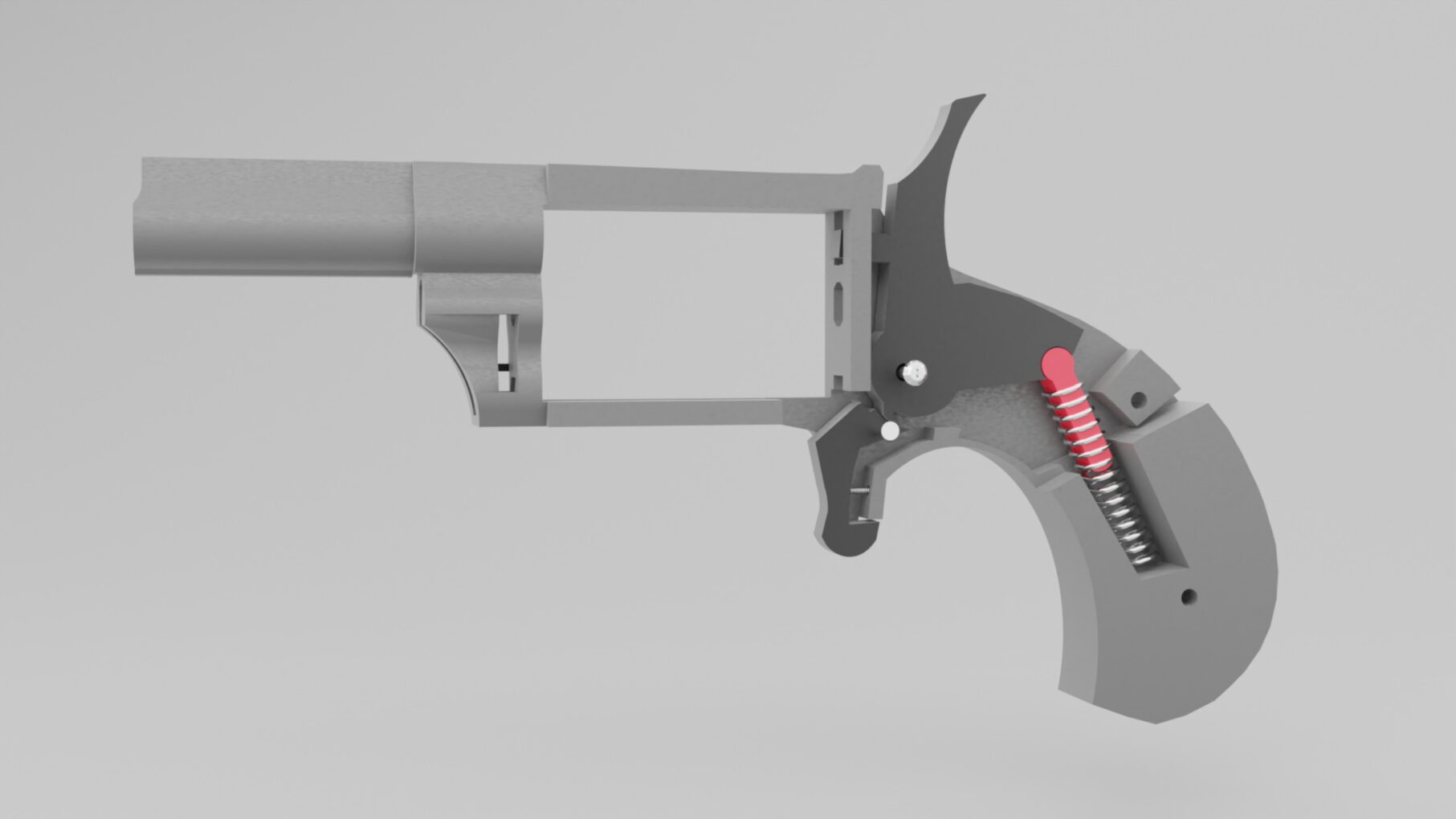

- All part separated for easy texturing.

- All colours can be easily modified.

- You can get access to the original non-smoothed mesh.

Normals are directional vectors perpendicular to a polygon or surface. Each polygon

has a surface normal, and it should always be facing outwards.

- The model is designed to be easily assembled post-printing, with minimal supports required for printing.

- 1. Optimal Layer Height

- Tip: Choose a layer height that balances detail and speed. For high-detail prints, use a smaller layer height (e.g., 0.1mm), and for faster prints or larger models, a thicker layer height (e.g., 0.2mm or 0.3mm) can be used.

- 2. Use Appropriate Infill Density

- Tip: Adjust the infill density based on the purpose of your print. For strong, functional parts, an infill of 20-50% works well, while decorative models can use 10-15% infill to save material and time.

- 3. Print Speed and Temperature

- Tip: Reduce print speed for more intricate details and sharper corners. For most PLA prints, a speed of 50-60 mm/s and a nozzle temperature of around 200°C are good starting points. Adjust according to your filament type.

- 4. Support Structures

- Tip: Use supports only where necessary to minimize post-processing. Consider using tree supports or adjusting overhang angles to reduce the need for supports. You can also set up custom supports in your slicer for more control.

- 5. Bed Adhesion

- Tip: Ensure good bed adhesion by using a brim or raft for small or complex prints. Adjust the first layer height and print speed to ensure it sticks well to the bed. Level your bed properly and consider using adhesives like glue stick or painter’s tape if needed.

- 6. Cooling Settings

- Tip: Enable cooling fans for PLA prints to improve overhangs and bridging. For ABS and other high-temp materials, reduce fan speed or turn it off to avoid warping.

- 7. Retraction Settings

- Tip: Tweak retraction settings to minimize stringing. A typical starting point is a retraction distance of 4-6mm and a retraction speed of 25-45 mm/s. Adjust based on the material and your printer’s performance.

- 8. Wall Thickness and Top Layers

- Tip: Increase wall thickness and add extra top layers for a stronger print and to avoid gaps in the top surface. A wall thickness of 1.2mm (3 lines with a 0.4mm nozzle) and 5-6 top layers are generally sufficient.

- 9. Optimize Supports for Easy Removal

- Tip: Use the “Support Z Distance” setting to create a small gap between the support structure and your model, making it easier to remove the supports without damaging the print.

- 10. Check for Print Time and Material Estimations

- Tip: Always check the estimated print time and material usage in your slicer to ensure you have enough filament and to plan your print accordingly. Adjust settings if the time is too long or if you want to save material.

- These tips should help you get the most out of your 3D printing projects. Happy printing!