Here’s a complete, easy-to-understand list of ALL major types of 3D printing technologies, grouped by category

Material Extrusion

(Most common – FDM printers)

Vat Photopolymerization

(Resin-based printing)

Powder Bed Fusion

(Industrial & high strength)

Binder Jetting

Use: Casting molds, metal parts

Here’s a comprehensive list of the most popular FDM/FFF 3D printer filaments

Metal Filaments (BASF Ultrafuse Series)

Stainless Steel (316L) – Good all-purpose metal with corrosion resistance

PC (Polycarbonate)

(Pros: Very strong, heat-resistant, durable.

Nylon (Polyamide)

Pros: Strong, durable, slightly flexible, chemical-resistant.

PLA ABS PETG TPU / TPE

Pros: Tough, flexible, chemical-resistant, minimal warping. TPU / TPE (Flexible Filaments) Pros: Flexible, impact-resistant, elastic

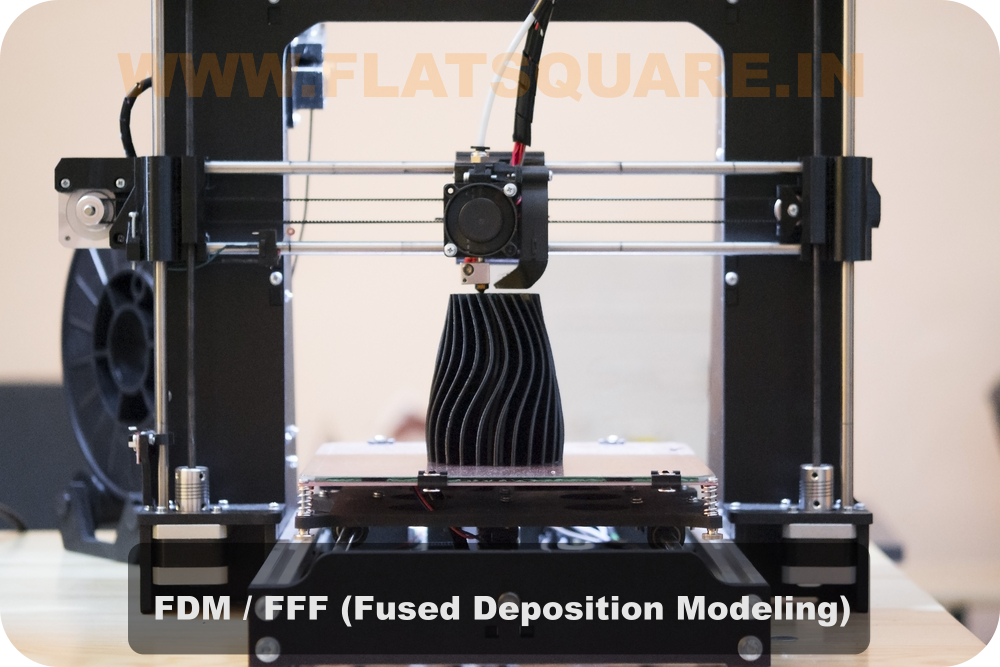

🔹 1. Material Extrusion

(Most common – FDM printers)

▪ FDM / FFF (Fused Deposition Modeling)

-

Melts filament and deposits layer by layer

-

Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber, BASF filaments

-

Use: Hobby, prototyping, functional parts

-

Examples: Ender 3, Prusa, Bambu Lab

🔹 2. Vat Photopolymerization

(Resin-based printing)

▪ SLA (Stereolithography)

-

Laser cures liquid resin

-

Very high detail

-

Use: Dental, jewelry, miniatures

▪ DLP (Digital Light Processing)

-

Projector cures entire layer at once

-

Faster than SLA

▪ MSLA / LCD

-

LCD screen masks UV light

-

Most popular resin printers today

-

Examples: Anycubic, Elegoo

🔹 3. Powder Bed Fusion

(Industrial & high strength)

▪ SLS (Selective Laser Sintering)

-

Laser sinters nylon powder

-

No support structures needed

-

Use: Functional mechanical parts

▪ DMLS / SLM (Metal Printing)

-

Fully melts metal powder

-

Materials: Steel, Aluminum, Titanium

-

Use: Aerospace, firearms parts, medical implants

▪ MJF (Multi Jet Fusion – HP)

-

Uses fusing agents + heat

-

Stronger & smoother than SLS

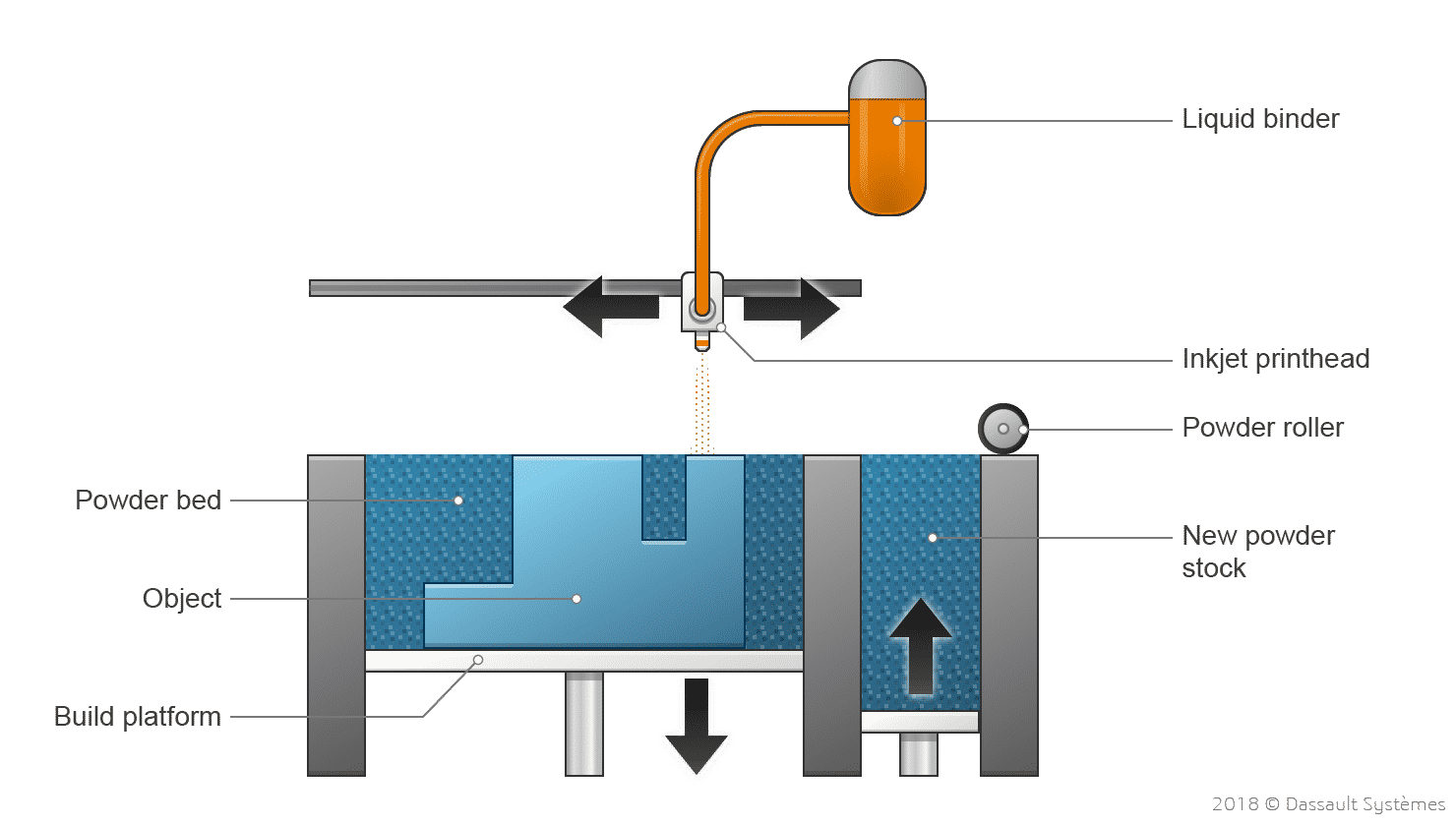

🔹 4. Binder Jetting

▪ Binder Jetting

-

Liquid binder joins powder

-

Can print metal, sand, ceramic

-

Requires post-processing (sintering)

Use: Casting molds, metal parts

🔹 5. Material Jetting

▪ PolyJet

-

Inkjet-style resin droplets

-

Multi-color & multi-material

-

Use: Product design, medical models

🔹 6. Directed Energy Deposition (DED)

▪ DED / LENS

-

Metal powder or wire melted by laser

-

Can repair existing metal parts

-

Use: Aerospace, defense

🔹 7. Sheet Lamination

▪ LOM (Laminated Object Manufacturing)

-

Layers of paper/plastic/metal bonded

-

Low-cost, less common today

🔹 8. Concrete & Large-Scale 3D Printing

▪ Construction 3D Printing

-

Prints houses, walls, bridges

-

Material: Concrete mixtures

🔹 9. Bioprinting

▪ Bio 3D Printing

-

Prints living cells

-

Use: Medical research, tissue engineering

🔹 10. Hybrid & Special Types

-

Continuous Fiber Printing (Markforged)

-

Multi-material printing

-

4D Printing (shape-changing materials)

🔧 Summary Table

| Category | Technology | Common Use |

|---|---|---|

| Filament | FDM | Home, DIY, functional |

| Resin | SLA / DLP / MSLA | High detail |

| Powder | SLS / SLM / DMLS | Industrial |

| Jetting | PolyJet | Multi-color |

| Metal | DED | Aerospace |

| Construction | Concrete Printing | Buildings |

| Medical | Bioprinting | Research |

Here’s a price guide for FDM / FFF 3D printers in USD (approximate retail prices — actual can vary by region, sales, and availability):

📍 Budget / Beginner ( ~$200 – $500) Anycubic Kobra 2 Neo Beginner FDM 3D Printer — ~$150–$300 (entry-level, great for hobbyists & beginners) Other similar models: Creality Ender / K1 class, Flashforge Adventurer (~$200–$400) 🛠 Mid-Range / Prosumer (~$500 – $1,500) Creality K2 Pro 3D Printer — Around ~$900–$1,200 (features dual cameras, smart leveling) Bambu Lab X1E 3D Printer — ~$1,400–$1,500 (fast prints, advanced features) Other examples: Prusa MK4 (~$1,049–$1,399), Bambu Lab P1S (~$900+), Flashforge Adventurer Pro (~$400+ with features) 🏭 Professional / Large Build (~$2,000+) FlashForge Guider 3 Ultra Dual Extruder — ~$3,500+ (large build volume, dual extruders) Flashforge Creator 3 — ~$1,200+ (mid-high range desktop) FFF FDM Dual Head 3D Printer Machine — ~Industrial estimate (often $3,000+) — varies widely

Here’s a price overview of Vat Photopolymerization (SLA/DLP/MSLA) 3D printers in USD, from budget hobbyist models to more advanced systems 👇

🖨️ Entry-Level / Budget Vat Photopolymer Printers (Good for hobby & miniatures) Anycubic Photon Mono 4 3D Printer – ~$150–$250 equivalent (entry hobbyist resin printer) — very popular for high-detail prints. HALOT R6 2K Resin 3D Printer – ~$120–$220 (LCD/DLP entry resin printer). 💡 Typical desktop resin printers in this category often go from ~$200 up to $500 for good LCD/MSLA machines. 🏡 Mid-Range / Enthusiast Resin Printers ELEGOO Mars 5 Ultra 9K Resin 3D Printer – ~$300–$450 (large build volume & higher resolution). ELEGOO Saturn 4 Ultra 16K Resin 3D Printer – ~$600–$900 (high-resolution, larger prints). 📊 Mid-range resin printers typically cost $400–$1,000, with features like 8K–16K LCD panels and larger build volumes. 🏢 Advanced / Premium Resin Printers Anycubic Photon MONO M7 MAX 3D Printer – ~$700–$1,000+ (larger format and faster printing speeds). 📈 Beyond this, many professional SLA/DLP machines are priced $1,000–$5,000 for more robust engineering-grade models, and $10,000+ for industrial systems used in dental, jewelry, or manufacturing sectors.

typical Powder Bed Fusion Price Ranges (USD)

🏭 Industrial Metal PBF Machines (DMLS / SLM / LPBF) These are true powder bed fusion metal printers with lasers and inert gas systems — used in aerospace, medical, automotive, and high-precision manufacturing: Entry-level industrial PBF (small build size): ~$90,000 – $150,000+ (e.g., Xact Metal or One Click Metal style laser PBF systems). Mid-range industrial systems: ~$250,000 – $500,000+ (e.g., EOS M100, Renishaw RenAM 500S-class). High-end / production-scale PBF: $500,000 – $1.5M+ (multi-laser, large build volumes). 👉 Most serious metal PBF machines start well above $100,000 and can go into the millions depending on build size, lasers, automation, and certification. 🧪 Polymer SLS (Plastic Powder Bed Fusion) Research / bench SLS systems: ~$5,000 – $30,000+ — smaller setups sometimes used in labs and development. Professional plastic SLS machines: ~$200,000 – $500,000+ — larger build volumes, better reliability and industrial performance.

Binder Jetting 3D Printer Price Ranges (USD)

Lower-Cost / Entry / Desktop-ish Options Small or experimental binder-jet printers in listings can appear ~$18,000 – $25,000 — often limited in capability, basic metal/sand printing. Example budget options often seen online in industrial listings: ~$18,500 – $25,000 for smaller binder jet machines. 🏭 Industrial & Mid-Range Binder Jetting Printers Typical industrial binder jet systems: ~$30,000 – $200,000+ depending on build volume and precision. Example mid-range machines from Chinese suppliers: around $80,000+ USD. 💼 Advanced / Production Industrial Systems Fully-featured machines for metal production or mass parts can be $200,000 – $400,000+, and even beyond for automated lines. Some specialist industrial machines listed near $330,000 – $400,000. Highly optimized system bundles (printer + furnace + depowdering) such as Desktop Metal Shop System start ~$150,000 – $225,000 for metal binder jet setups — not including post-processing.